Research and innovation

Opportunities and limits of circular economy and superior use of wood chip residues - „RestUse“

The research project „RestUse" aims to identify and evaluate new ways in which residual materials from woodchip processing (e.g. fines particles, needles) can be put to higher-value use. One main goal is investigating whether such residues are suitable for nutrient recycling in the forest ecosystem to mitigate nutrient extraction caused by wood harvesting measures.

Background

Why residual materials from wood chip processing should be put to higher value use?

Figure 1: Success of technical sieving of wood chips (© Kuptz, TFZ)

Drying and sieving – two steps of wood chip processing for a higher fuel quality

Zoombild vorhanden

Zoombild vorhanden

Figure 2: Sieving as an important processing step for fuel processing; here: drum sieve (© Schreiber, LWF)

Sieving removes residual material such as fine particles, overlength, and needles from the wood chips. Although these residues contain a relatively large proportion of nutrients and organic compounds, they can have a negative effect on combustion and the heating plant. Especially high shares of fines and needles lead to higher emissions and ash content as well as slagging.

Project approach

In a field study, the application of residual materials in the forest and their influence on the nutritional supply of two forest stands will be investigated by sampling needles and soil. Based on the acquired field data and the practical study, a possible "fertilization effect" and an ideal residue particle size could be deduced and recommended to relevant stake holders.

Figure 3: Overview of the work packages in the 'RestUse' project.

Work package „Market analysis“

Around one third of the 143 respondents stated that they screen wood chip assortments. In 68 % combine this step with technical drying. Almost half of all respondents use a barrel sieve, around a quarter use a flat screen and 17 % use a star screen. Other sieves were hardly ever used.

The interviewees were also asked about the wood assortments for their respective preparation process. There were clear differences in the assortments used for participants inside and outside of Bavaria. In Bavaria, residual forest wood chips made from coniferous wood are the most commonly used assortment for screening at 55 %. Outside Bavaria, residual forest wood chips from hardwood assortments and energy roundwood chips from coniferous wood are mainly used as raw materials for the wood chip production. This means that higher quality assortments tend to be screened outside of Bavaria.

The screening process usually produces three fractions:

- Main fraction

- Fine fraction/residual materials

- Overlength (is usually shredded again, depending on the treatment process)

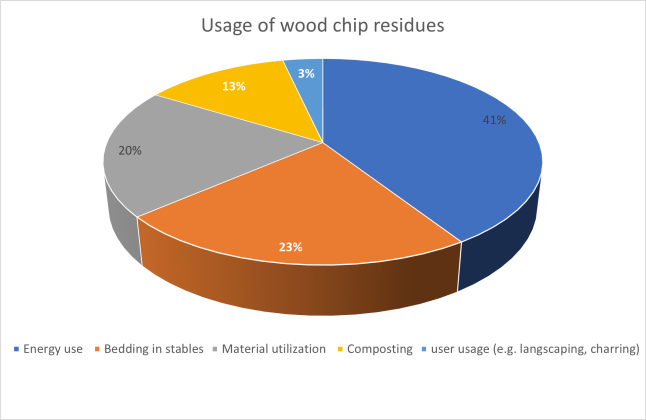

Energy use also dominates the use and marketing of the fine fraction/residual materials at around 40 %. The second most common use of the residues is bedding in stables at 23 %, followed by material utilization at 20 % (e.g. as mulch material). A small proportion (13 %) of the fine fraction is used for composting or in other areas, such as landscaping or for charring (see Figure 4).

Figure 4: Usage of wood chip residues

Work package „Case studies on established utilisation pathways“

An innovative method for analysing the screening residue was developed for this purpose. After drying the screening residues, the sample is fractionated into the following particle sizes on a horizontal sieve shaker:

- 45 mm

- 31.5 mm

- 16 mm

- 8 mm

- 3.15 mm

- 1 mm

- < 1 mm

Figure 5: Examples of respective particle sizes

Work package „Field study“

Background

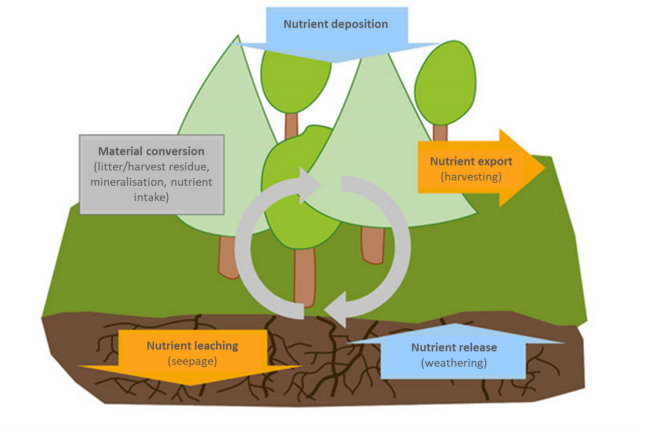

Figure 6: Schematic representation of nutrient flows in managed forests (© Weis et al. 2016)

Method

Two different sample areas were selected: a 75-year-old old spruce stand (see Figure 5) and a 30-year-old spruce thinned stand (see Figure 6). This allows a deduction about possible effects of the various application types, and also about the influence of age.

Needle sampling

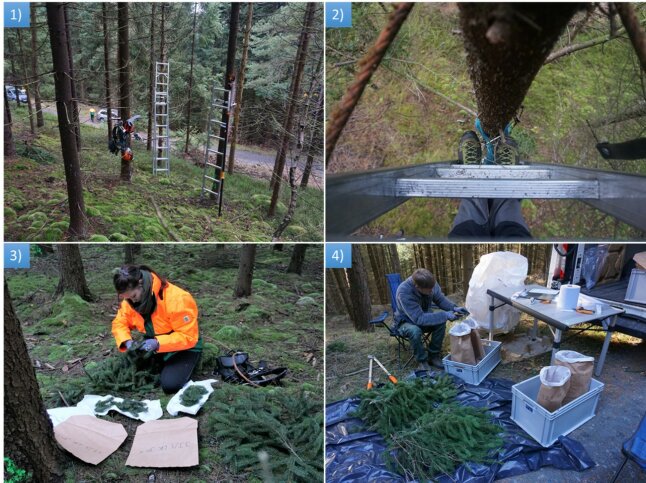

Figure 9: Needle sampling of the young spruce stand. Extraction of the sampling branches (1 & 2) and on-site separation of the needle years (3 & 4).

Figure 10: On-site needle sampling (older spruce stand).

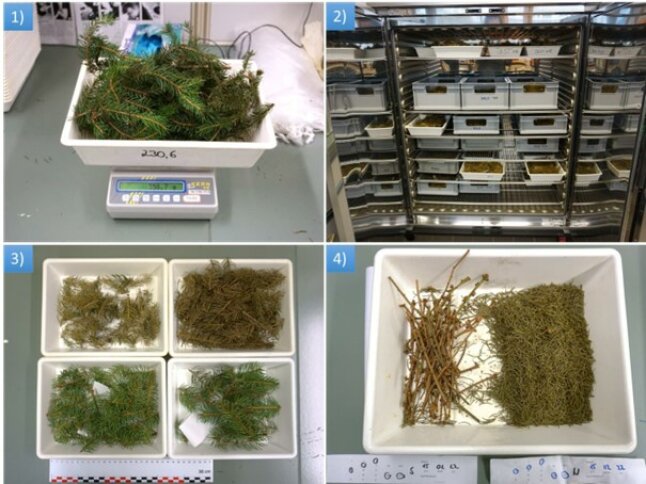

After transportation to the LWF-laboratory, all samples were weighed in “fresh” and subsequently dried, to determine the water content of the needles. Afterwards, the needles were separated from the twigs (see Figure 11). A first analysis of the needles was the so-called "100-needle weight”, which serves as a simple vitality parameter. It is determined by the average mass [g] of 3 x 100 needles per sample. The samples were then finely ground using an ultra-centrifugal mill. The needle samples are currently being analysed for element content using a benchtop XRF-device.

A total of three sampling campaigns were carried out to obtain the needle samples:

- 1st sampling – record of the initial state: winter 2021/22

- 2nd sampling - 8 months after the application: winter 2022/23

- 3rd sampling - 20 months after the application: winter 2023/24*

* Only sampling of the young spruce stand: a majority of the old spruce stand had to be felled in early summer 2023 due to a massive bark beetle infestation

Figure 11: Preparation of needle samples in the laboratory. 1) Weighing the fresh samples. 2) Drying at 60°C. 3) Difference between fresh and dried sample. 4) Separation of the needles and twigs.

Soil sampling

Figure 12: Humus sampling with a 20 x 20 cm frame

Figure 13: Sampling of the topsoil with a stem drill

Figure 14: soil sampling with core drive sampler

All samples were brought to the LWF lab and dried. After drying, the soil samples are first sieved to 2 mm and then ground in order to analyse the element contents.

Application of different variants

- Woodchip screening residues with 8 mm screen diameter,

- Woodchip screening residues with 16 mm screen diameter

-> both residues were produced with a barrel sieve from a standard residual wood chip assortment - Modified screening residues (8 mm + mycorrhiza)

-> The mycorrhiza "vaccination" is intended to support the exchange of nutrients with the tree and is acclimatised for spruce trees (ectomycorrhiza) - Lime fertilizer with 30 % wood ash

-> The lime fertilizer is a commercially available natural lime product specifically for forestry usages. It is made from moistened dolomite lime mixed with 30 % wood ash - Control area, untreated

Field applicationof the variants

Results

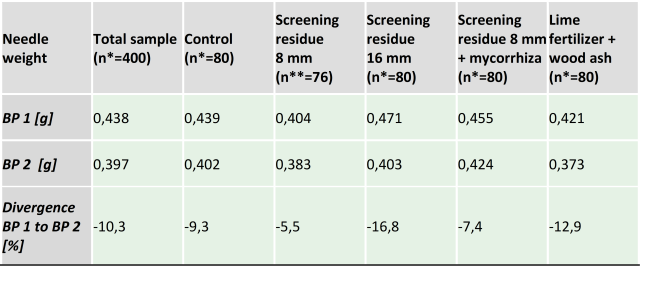

Results of the 100-needle weight of the 1st and 2nd sampling campaign (BP1 and BP2)

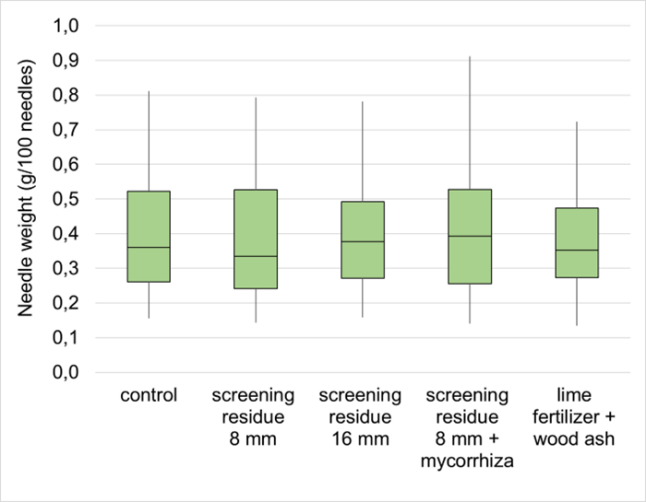

Figure 17: Variance in needle weight of the 2nd sampling between the variants of the application trial

- Higher needle weight in sunlit crown (vs. shaded crown) and old spruce stand (vs. young/thinning stand)

- No significant differences between the variants

* N of BP 1 and BP 2; ** 1 sample tree was removed due to bark beetle infestation infestationskäferbefall vor BP 2 entnommen

- Decrease in all variants (incl. control area)

- Significant decrease especially in the newly formed needle year of the 2nd sampling

- Signs of stress caused by several years of drought and bark beetle infestation

Outlook

Contact

Project information

| Short Title | RestUse |

| Long Title | Opportunities and limits of circular economy and superior use of wood chip residues |

| Status | In progress |

| Project Manager | Markus Riebler |

| Deputy Project Manager | Dr. Herbert Borchert |

| Project Consultant | Katharina Wendel |

| Duration | 1st January 2021 – 31st October 2024 |

| Funding | Bavarian State Ministry of Food, Agriculture and Forestry |

| Funding Code | G2/N/20/11 |